1. This safety operation procedure must be familiar with before using lifting tongs.

2. Before use, the wear and deformation of hoisting shall be checked, and the inspection results shall be recorded in the inspection record. The hoisting shall be free of cracks, sharp corners, burrs, corrosion, warpage, torsion and other harmful defects. Check whether all rotating parts can rotate flexibly and whether fasteners can not be loosened. If the cross-section of the stressed member is worn or corroded to 10% of the original size or the jaw opening is increased by 10% compared with the original size, it must be scrapped and shall not be used.

3. The horizontal lifting tongs can only be used for horizontal lifting of steel plates. It is strictly prohibited to use them for other purposes.

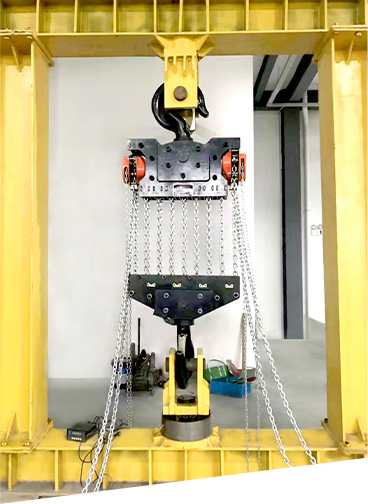

4. Different horizontal tongs shall be selected according to the length and width of the steel plate and different stacking conditions. Lifting tongs with fixed beams must be used to lift long iron plates. If a short steel plate or a single steel plate is hoisted, non fixed lifting tongs can be used. No matter what kind of lifting tongs are used, they can only be used in pairs, and the thickness of the hoisted steel plate shall not exceed the specified thickness of the jaw.

5. It is forbidden to lift from above. Do not collide with other objects during lifting. The crane operator must assist the crane driver to remind the personnel of the object running direction, so as to avoid injury accidents.

6. Any lifting tongs shall not be used with excessive rated load. (that is, the rated load refers to the maximum weight allowed to be lifted when the included angle of lifting points is 60 ° when the tongs are used in pairs.)

7. No matter what kind of lifting tongs, they must be clamped in place according to the instructions and procedures, and can be lifted only after they are confirmed to be locked