Types Of Electric Wire Rope Hoist

Electric Wire Rope Hoist Working Principles

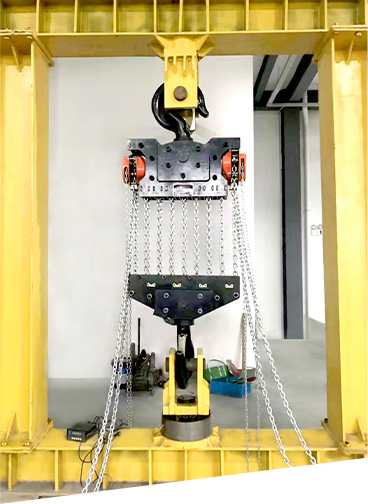

How does a electric wire rope hoist work? Not like manual hoist driven by manpower, electric wire rope hoist realize cargo lifting by motor driving. Structured with electromagnetic brake, lifting motor, travelling motor (if hoist come with moving trolley), hook, drum, wire rope, gear set, control box, limit switch and control panel.

To use the electric wire rope hoist, you need to installed it on the I-beam or connect with a moving trolley which seat on the I beam. The operators can simply push the button of up, or down, or emergency stop to control the cargo movement. All our electric hoist has the power failure protection function, you don’t need to worry about the potential risks of cargo drop in case of power failure.

Power Supply Requirement

Most of the electric wire rope hoist are designed for industrial purpose, so they normally required three phase power supply which can provide enough power to drive the motor under heavy lifting. Single phase is more available for electric chain hoist with the capacity under 3t or the mini wire rope hoist that normally can lift up to 1200kgs maximumly.

Tips For Test And Safe Operation Of The Electric Wire Rope Hoist

1. Before first operation of the new installed electric wire rope hoist(new products or reassembly hoist), check and ensure all the components have been installed and not powered on. When everything get ready, carry out a no-load operation to be sure the hoist can work properly.

2. All our electric wire rope hoist have been conducted a static load test at 125% of the rated load, about 100mm above the ground for 10 minutes, and all the parts are checked in good condition.

3. All our electric wire rope hoists have been dynamic load test tested under rated load by continues up-down, left-right( trolley type) movement. All the mechanical transmission parts, electrical parts and connecting parts are normal and reliable.

4. In use, overload and exceeding the rated duty are prohibited.

5. During installation and maintenance, the limit device should be checked for flexibility and reliability. When the hook rises to the limit position, the distance from the hook to the drum must be greater than 50mm (10t, 16t, 20t must be greater than 120mm). When the hook drops to the lower limit position, the safety ring of steel wire rope on the drum shall be ensured, and the effective safety ring must be more than 2 turns.

6. Do not press the up and down or left and right buttons at the same time to make the electric hoist move in the opposite direction.

7. The electric hoist shall be operated by a specially assigned person, and the operator shall fully master the safety operation procedures. Do not pull and hoist at angles.

9. During use, special personnel must regularly check the electric wire rope hoist, take timely measures in case of faults, and carefully record them.

10. When adjusting the braking sliding amount of electric hoist, ensure that the braking sliding amount s ≤ V / 100 under rated load (V is the distance of stable lifting within one minute under load).

11. Keep enough lubrication oil in use and keep the lubricating oil clean without impurities and dirt.

13. When oiling the steel wire rope, a hard brush or small wooden pieces shall be used. It is strictly prohibited to oil the working steel wire rope directly by hand.

14. When the electric hoist is not working, it is not allowed to hang heavy objects in the air to prevent permanent deformation of parts.

15. If any fault is found during use, the main power supply shall be cut off immediately.

16. Special attention shall be paid to the wearing parts during use.